Hosting open hardware files on Zenodo: Durable and citable resource sharing

2021-05-18

Press: 3Dneuro featured in Dutch newsletter Bionieuws

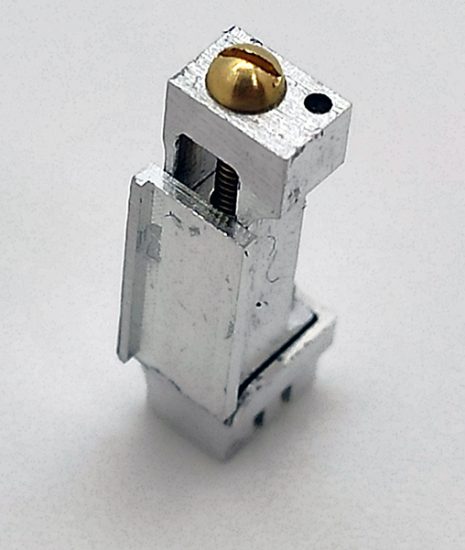

2022-06-15This week, we announced on Twitter a preorder round for our first production run of the R2Drive. This microdrive was designed by the Buzsáki lab at NYU, with a focus on sustainability: One can reuse the drive and the silicon probes, with the main limitation being electrode impedance.

We planned for a 50-drive batch, machined in aluminum. That manufacturing process was particularly beneficial in 2 ways compared to 3D-printing in stainless steel:

(1) Cost reduction. We can deliver fully assembled drives for less than the cost of printing the parts yourself.

(2) Weight reduction. The aluminum R2Drive weighs only 0.47 g, half as much as the stainless steel version. Lighter implant, happier animals!

Given that, it makes sense that all 50 drives were claimed in under 24h! We are now planning to ship the first 50 and arranging a 2nd production run so that everyone who preordered gets their drives no later than July-August. The first orders will ship in June.

More information on preordering: www.3dneuro.com/products/r2drive-preorder/

More information on R2Drive: buzsakilab.github.io/3d_print_designs/

1 Comment

hi,

My name is Winnie and I am a researcher at the Buzsaki lab.

We are wondering if you can give us a quote for 16 R2D metal drives?

Thanks very much,

Winnie