Methods preprints!

2024-03-08

Revising our pricing and growth strategy

2025-04-03Our first microdrive was based on a single idea: Protect the silicon probe! To achieve that, we often flirted with the limits of 3D printing. The result was a lightweight protective carrier for probes that proved pretty effective. Our local collaborator routinely implanted 3 probes per animal.

We are phasing it out for 2 reasons. First, when Vörölsakos et al. (2021) invented the detachable base for microdrives, the odds of probe breakage went down significantly(we make it, see R2Drive). This made the added protection of the 3Drive shield less critical. Second, 3D-printed parts do not keep the same properties across time. Especially the type of plastic we needed for fine detail prints, which becomes brittle: So if we maintained stock, or if the user stored the microdrives for months before use, they could perform sub-optimally.

Below we archive some information on the 3Drive.

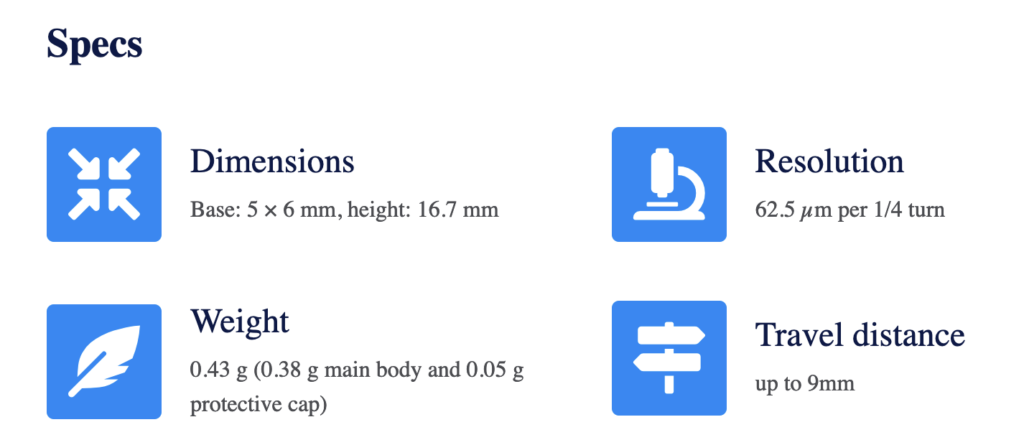

Weighing less than 0.5 g, the 3Drive also features a small 5×6 mm footprint that makes it suitable for implants both in freely behaving and head-fixed animals (mice and rats primarily). It minimizes the risk of silicon probe damage, literally acting as armor for your probes – providing protection before and during the experiment. And with some practice, the probes can be recovered when you’re done. So while the 3Drive is not reusable, your probes very much will be.

The 3Drive carries any silicon probe with a flexible polyimide cable, a common feature of probes for chronic recordings. Including Neuropixels probes. One advantage of the flex cable assembly is that it reduces the mechanical coupling between the probe itself and the connector/headstage/tether cable. Our multipurpose crown (see accessories below) secures the connector/headstage without glue/cement, further ensuring probe reuse.

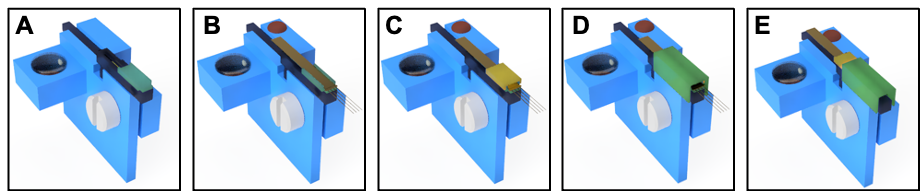

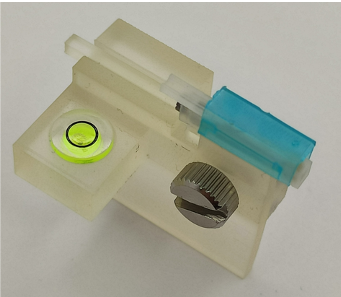

Assembly: The chronic probe’s flex cable simply ‘clicks’ into the 3Drive’s shuttle (Figure below, B). A drop of glue is then added for safety and the bottom half of the drive is covered by a protective cap (D). This creates a secure space to retract the probe shanks (E). The assembly process is made even safer with our custom assembly holder.

Publications using the 3Drive

https://www.jneurosci.org/content/41/32/6864

https://www.researchsquare.com/article/rs-123425/v1

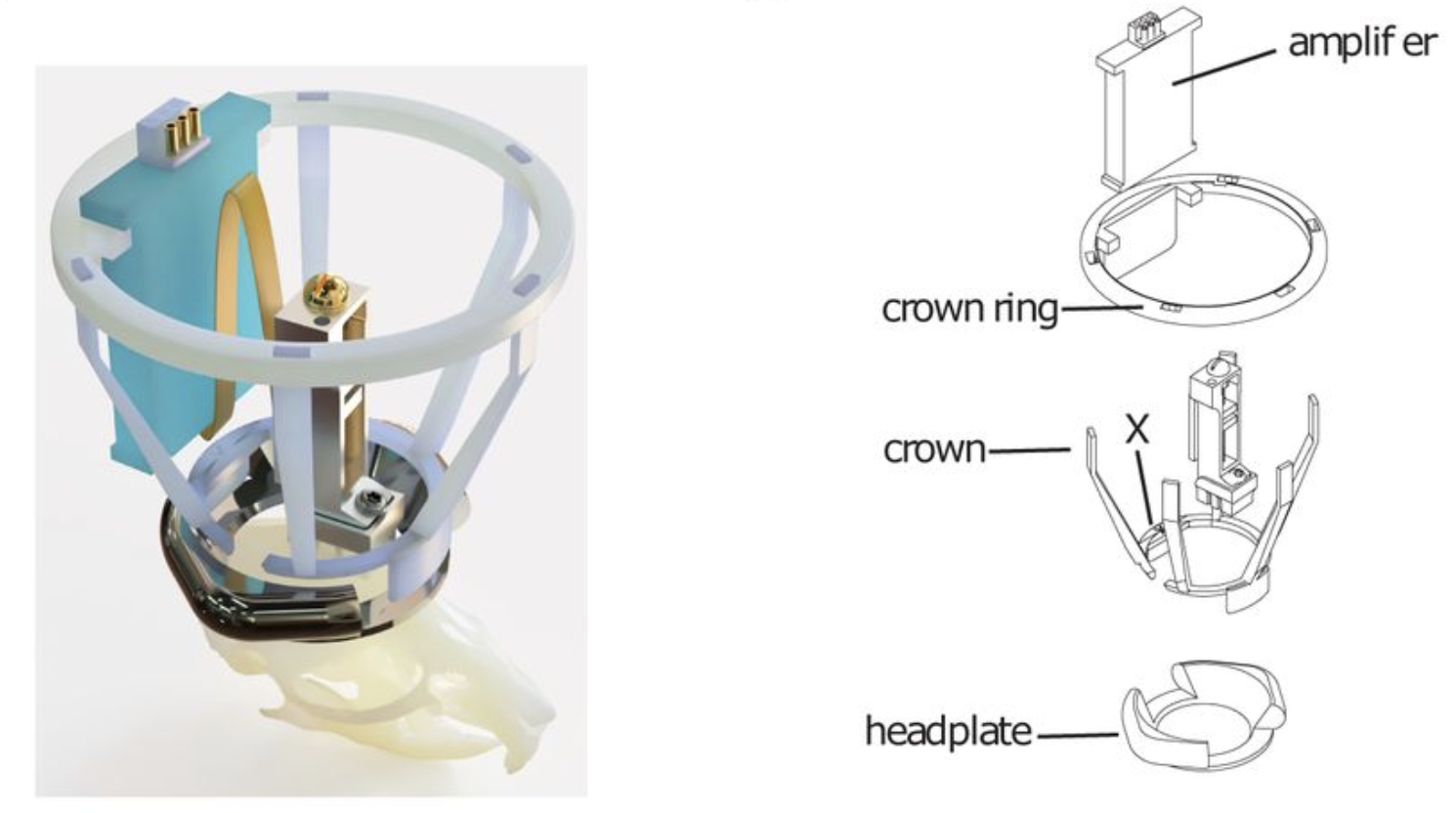

Multipurpose crown

There are many ways to protect your implants. Trying to find a balance between flexibility and ease, we developed the multipurpose crown. This protective frame, implanted around your drive, provides an in-built holder for an Omnetics connector, as well as a light support structure for a Faraday cage. The design also optionally features two contact points that enable stable head fixation for behaving mice. See a short video for how to handle the crown here.

Holders

To handle your probes with maximum safety.

Probe breakage can happen at any time that you handle them. Indeed, to minimize tissue damage, probe shanks are manufactured as thin as possible, making them fairly fragile. Once your probe is mounted onto the 3Drive, it is safe. Before that, to minimize the risk of breakage, proper tools and procedures are needed. That is why we have developed our holders.

Assembly holder

This holder was designed to securely mount your probe on the 3Drive.

Implantation holder

This holder is used during the implant surgery. It attaches to your stereotaxic arm, and includes 2 hooks that serve as support for the connector.